TIM Tester

Thermal resistance Rth

and thermal conductivity λ of materials

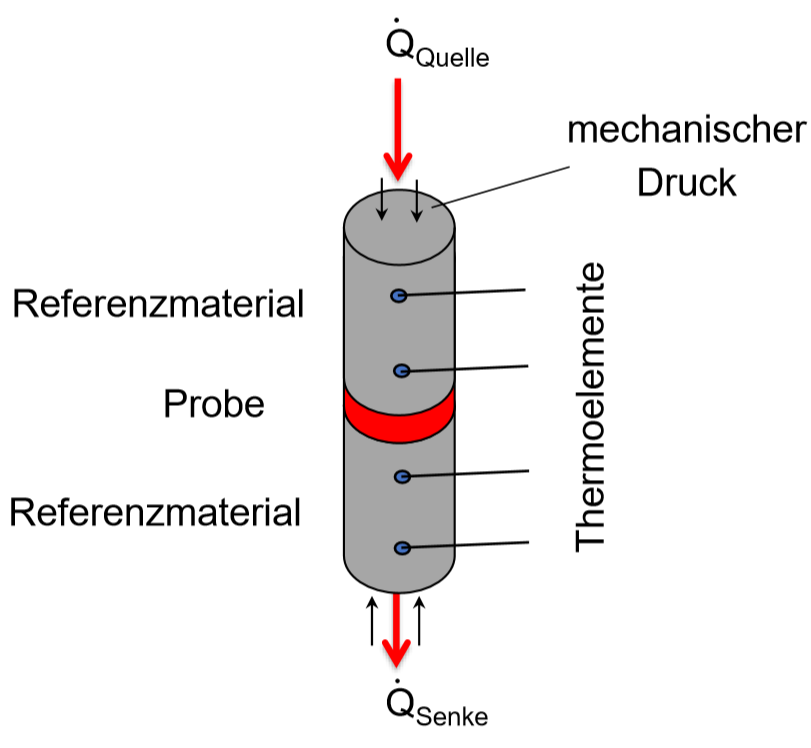

The TIM Tester is a test device developed by ZFW for the investigation of heat-conducting and insulating materials, such as gap fillers or pads, adhesives and foils, etc. Furthermore, substrates as well as solids can be thermally analyzed. The development of the device began in 2012 and has been continuously developed and improved since then.

The TIM tester has now established itself on the market. The test device is used in many well-known corporations, especially for examining gap fillers.

The test stand enables a precise measurement of the (effective) thermal resistance Rth

of a sample. Due to the high-precision resolution of the gap measurement (measurement of the layer or sample thickness), the thermal conductivity λ of the material can also be determined.

By measuring different layer thicknesses, it is possible to determine the contact resistance between the heat-conducting material and the aluminum test surfaces of the device. In general, there are several measurement modes in the TIM tester, depending on the type of material being examined: For low-viscosity samples, the thermal resistance or the eff. Thermal conductivity as a function of the gap (layer thickness) can be measured without pressure, whereas for solid materials the thermal resistance is determined as a function of the contact pressure.

Measurements are generally made using the stationary cylinder method according to ASTM D5470, which has established itself as the standard test method for the heat transfer properties of thermally conductive electrical insulation materials.

Summary:

- Highly accurate measurement of the thermal resistance

- Measurement of eff. thermal conductivity due to precise gap measurement

- Determination of the contact resistance between the heat conducting material and the aluminum test

surfaces - Pressure- or gap-controles measurements possible

- Measurement is performed with the stationary cylinder method according to ASTM D5470

Compression and expansion tests (delamination test)

The mechanical properties of a TIM have a direct influence on its thermal behavior. During operation, there is often a mechanical load on the TIM due to thermal expansion. This thermally induced gap change between the heat source and sink, which occurs in real cases, can be mechanically simulated and dynamically examined in the ZFW TIM tester.

For example, classic 2K gap fillers can be tested under specified boundary conditions, derived from the respective installation situation, such as gap thickness, sample mean temperature, amplitude, direction of the gap change and its frequency. If the gap is narrowed, the material is compressed. As the gap becomes larger, the material is stretched, which often leads to peeling phenomena on the surfaces of the measuring cylinder. This is called "delamination".

During the investigation, the thermal (thermal resistance and effective thermal conductivity) and mechanical properties (gap and force) of the TIM are continuously recorded. As a result, qualitative and quantitative statements can be made about the change in the thermal and mechanical properties of the TIM depending on the number of cycles or the service life.

For example, classic 2K gap fillers can be tested under specified boundary conditions, derived from the respective installation situation, such as gap thickness, sample mean temperature, amplitude, direction of the gap change and its frequency. If the gap is narrowed, the material is compressed. As the gap becomes larger, the material is stretched, which often leads to peeling phenomena on the surfaces of the measuring cylinder. This is called "delamination".

During the investigation, the thermal (thermal resistance and effective thermal conductivity) and mechanical properties (gap and force) of the TIM are continuously recorded. As a result, qualitative and quantitative statements can be made about the change in the thermal and mechanical properties of the TIM depending on the number of cycles or the service life.

Example of a delamination test:

By enlarging the gap, tensile forces build up at the sample interface. If these forces are too great, adhesive failure ensues, so that the sample becomes detached from the interface, which leads to poorer contact and a strong increase in thermal resistance. The decreasing ability to conduct heat would often result in thermal failure in the real component.

The investigation can precisely determine the forces or gap values at which the TIM becomes detached, in order to be able to counteract thermal failure caused by a temperature-induced change in gap.

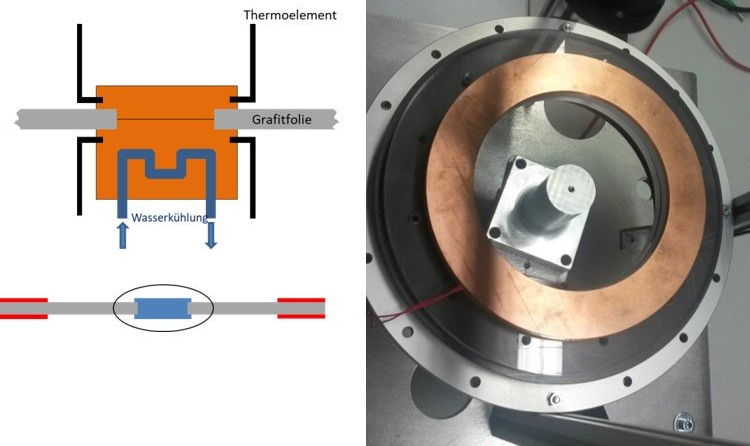

Inplane TIMTester

The Inplane-TIMTester enables the measurement of the thermal conductivity of graphite foils in the plane.

The principle is based on a stationary, ring-shaped heat impression with contactless temperature measurement via a high-resolution IR camera.